In the realm of engineering, the precision and clarity of drawings dictate the success of manufacturing, construction, and maintenance processes.

As industries increasingly move towards digital solutions to enhance accessibility, efficiency, and accuracy, the digitization of engineering drawings has become a critical endeavor.

Engineering drawing digitization involves converting detailed and complex physical drawings into digital formats, a process that not only preserves but also enhances the utility of original documents through advanced technologies.

This transition, however, is fraught with challenges. Engineering drawings, with their intricate symbols, precise connections, and extensive annotations, present unique difficulties that require sophisticated solutions.

From handling the sheer size and scale of these documents to accurately interpreting varied symbols and text, the digitization process must address multiple technical hurdles.

This article explores the multifaceted challenges of engineering drawing digitization and delves into the ways modern artificial intelligence systems can solve them.

Experience AI for Engineering Drawings

Engineering Drawing Digitization Challenges

Drawing Size

One of the most formidable challenges in the digitization of engineering drawings, particularly in process and instrumentation diagrams (P&IDs), lies in the sheer volume and complexity of the information each drawing contains.

It is estimated that a single page of a P&ID can feature approximately 100 different types of shapes, including a variety of symbols, connectors, and textual annotations.

Each symbol or connector is not just a graphic; it represents a specific component or function within the system, requiring precise recognition and classification during the digitization process.

The complexity multiplies when considering the scale required to represent an entire section of an industrial plant. Depending on the plant's size and complexity, the documentation could span anywhere from 100 to 1,000 pages.

This vast range underscores the variability and scale of projects within the industry. Digitizing such extensive documentation requires not only advanced scanning technology but also sophisticated software capable of managing and interpreting vast arrays of data efficiently.

The task is compounded by the need to maintain the integrity and accuracy of the information. Each component's placement, size, and connection type must be captured accurately to ensure the digital representation is as reliable as the physical document.

The digitization process, therefore, must be meticulously planned and executed with technologies that can handle large-scale data without compromising on detail and accuracy.

Symbol Recognition

A significant challenge in the engineering drawing digitization process is the accurate recognition and classification of equipment symbols, which are critical to the interpretation of engineering diagrams.

These symbols present inherent difficulties typical of classical machine vision challenges such as variations in lighting, scale, and orientation. Each of these factors can significantly alter how a symbol appears in a scanned image, complicating the task of consistent and accurate identification.

Further complicating the engineering drawing digitization process is the fact that different industries often adhere to distinct standards for their equipment symbols. For instance, the symbols used in a mechanical engineering drawing might differ markedly from those in an electrical diagram, not only in their appearance but also in their meaning.

Solution: Machine Learning For Symbol Detection

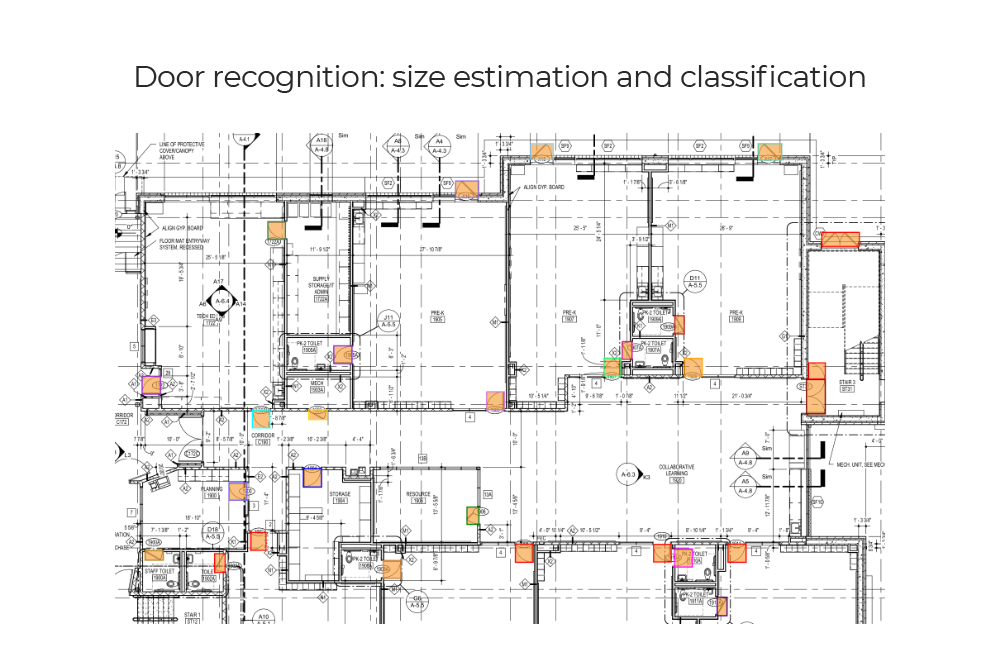

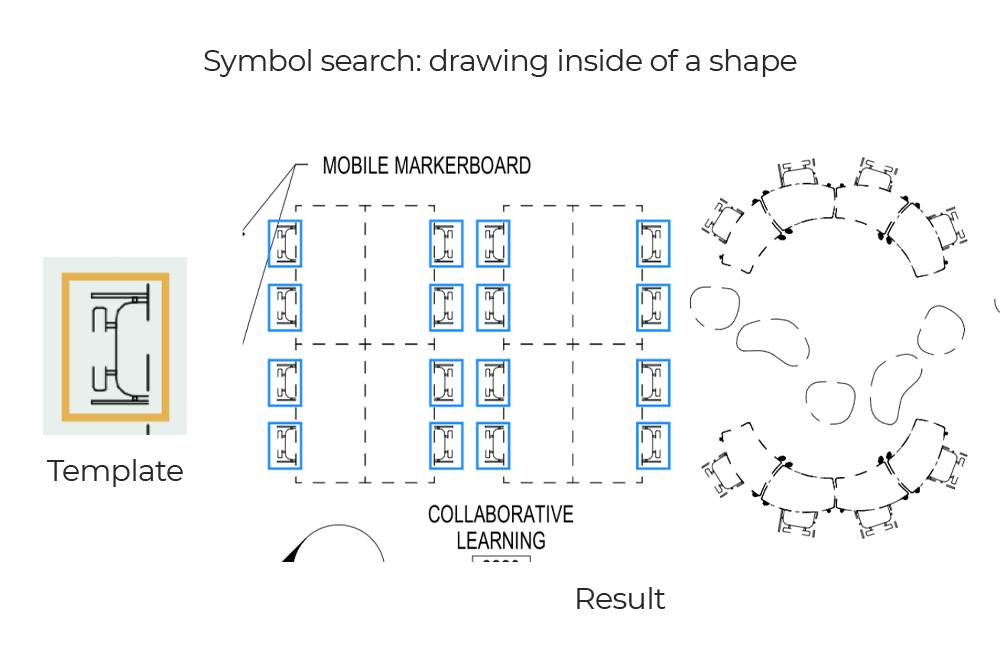

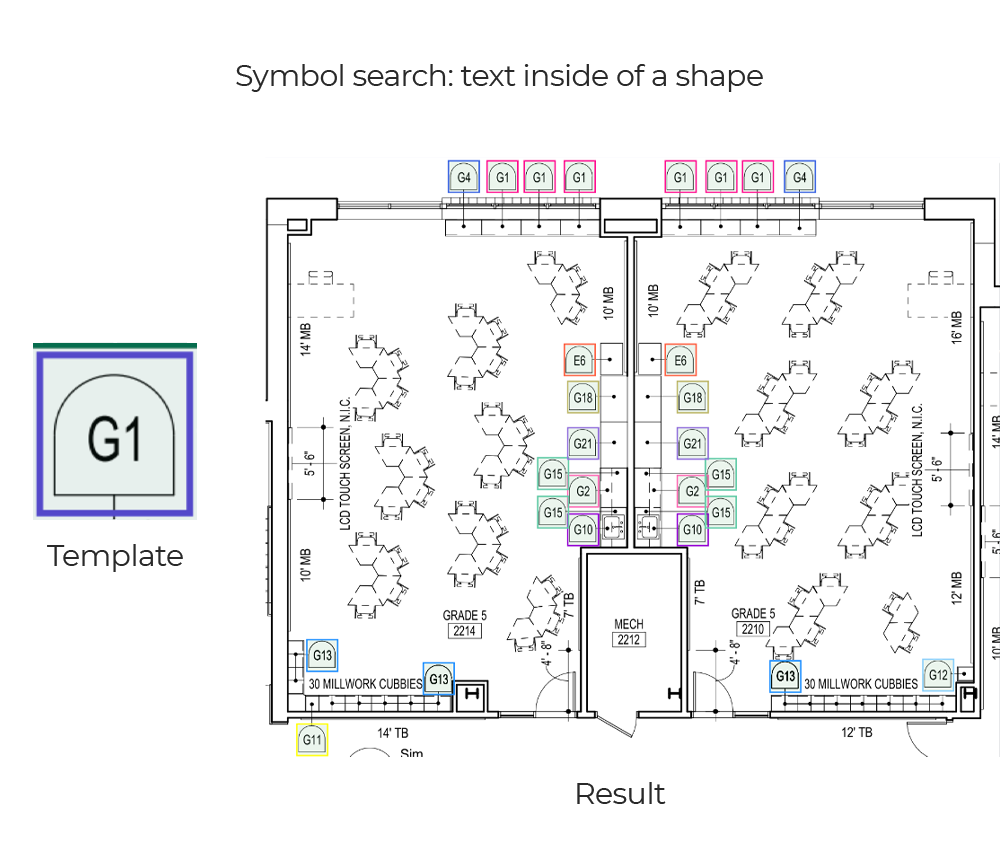

AI systems can perform targeted searches for specific symbols, including those highlighted by the user, enabling quick identification of structural elements like electrical symbols, plumbing icons, or material types.

Shape Detection

Engineering drawing digitization entails complex shape detection challenges that are crucial for the accurate interpretation and manipulation of engineering diagrams. This process involves recognizing a variety of geometric configurations and line styles, each carrying specific meanings within the drawing.

General Shape Detection

The ability to detect basic shapes such as arrowheads, cross-hatched areas, arcs, as well as dashed and dot-dashed lines is foundational in engineering drawing digitization.

Arrowheads, for instance, indicate flow direction or movement, making their accurate detection crucial for understanding operational sequences. Cross-hatched areas might denote materials or special surfaces, while arcs can signify ranges of movement. Dashed and dot-dashed lines often represent hidden or underlying features not visible on the surface, requiring precise identification to maintain the drawing's integrity.

Specific Shape Detection

Beyond general geometric forms, engineering drawing digitization also requires the identification of more complex symbol types, namely loop and loop-free symbols.

- Loop Symbols: These symbols are characterized by at least one closed primitive shape, such as a circle or oval, which often signifies continuity or feedback loops in circuitry and piping diagrams. Accurate recognition of these loops is essential as they can impact the interpretation of system functionalities or safety features.

- Loop-Free Symbols: Contrasting loop symbols, loop-free symbols are typically composed of single strokes or parallel line segments. These might represent linear elements such as resistors in electrical circuits or beams in structural designs. Recognizing these elements accurately is vital for detailed component analysis and assessment in various engineering fields.

The challenge in detecting these specific shapes lies not only in the variability of their appearance due to different drawing standards and conditions but also in their contextual significance within the overall diagram.

Solution: Computer Vision For Shape Detection

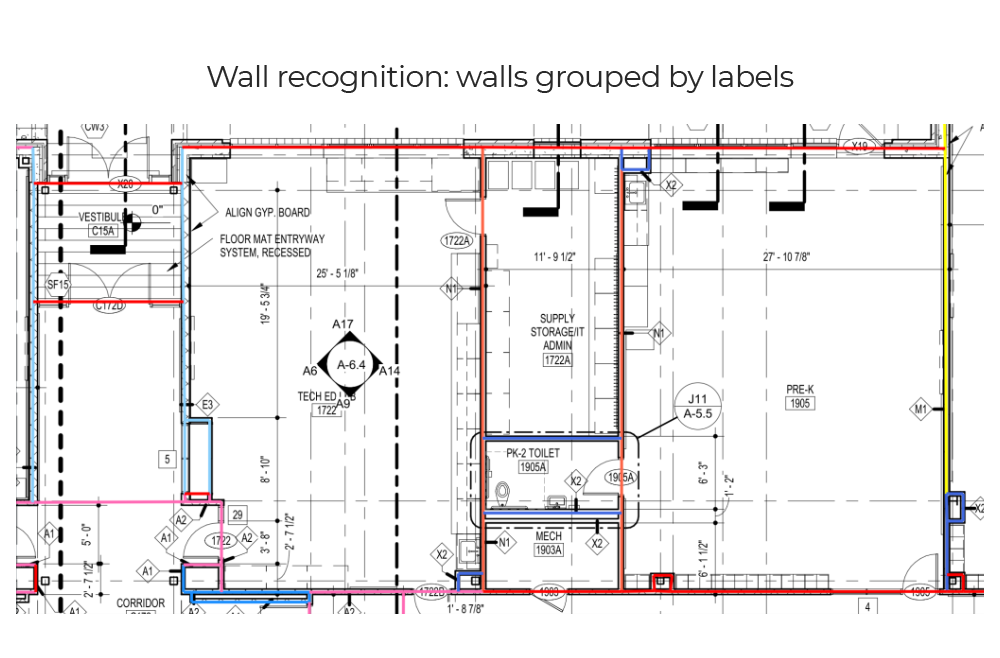

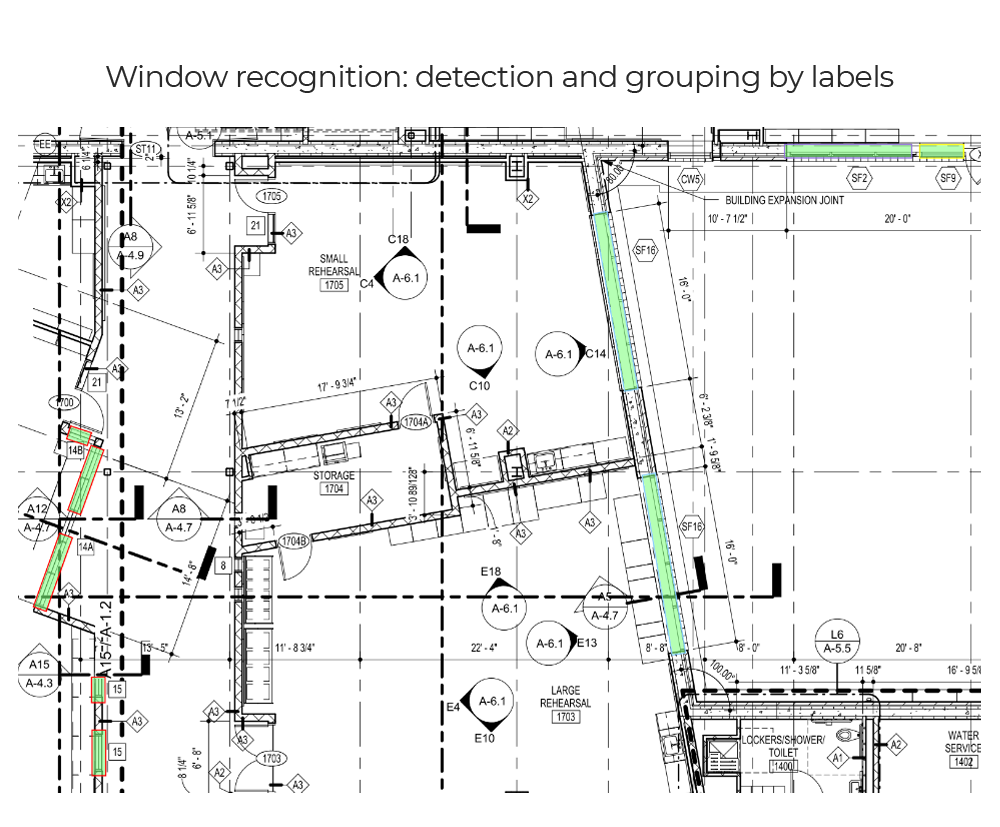

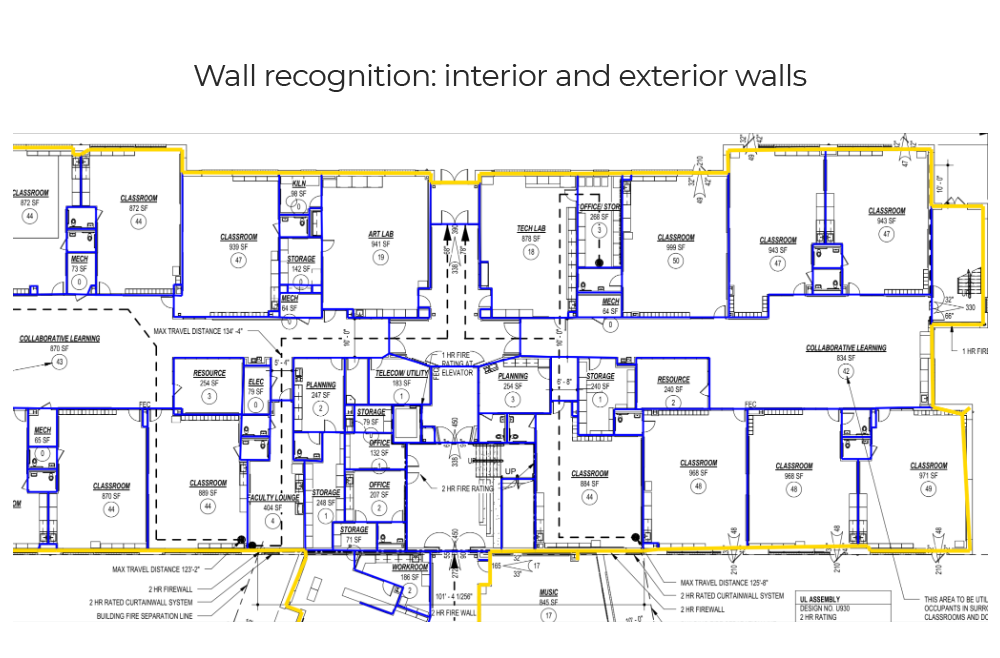

We at Businessware Technologies have had significant experience in creating systems for symbol and shape recognition in engineering drawings. Working on a system for architectural drawing system recognition, we have developed an AI module for detecting loop and loop-free symbols, like wall and room labels, electrical symbols, plumbing icons, or material types.

AI systems can be trained to recognise specific shapes, both loop and loop-free ones, with very high accuracy. The system can either detect these symbols and their types automatically or look for symbols identical to those specified by the user.

Objects marked by the same labels can be recognised and grouped together for quick and effective drawing analysis:

Connections

In engineering drawing digitization, accurately interpreting the myriad of connecting lines that define relationships between symbols is a significant challenge. These connections, which are essential for conveying both physical and logical relationships in engineering diagrams, can vary greatly in style and complexity.

Complexity of Connecting Lines

Engineering drawings, particularly complex diagrams like electrical schematics, control systems, or piping and instrumentation diagrams (P&IDs), often feature a dense network of lines.

These lines are not merely connectors; they represent critical physical paths like wiring, piping, or signal flows and logical relationships such as control sequences or operational hierarchies.

The complexity is heightened by the fact that these lines can intersect, overlap, and weave through one another, creating a tangled web that is difficult to decipher without precise digitization techniques.

Variability in Line Styles and Thickness

The representation of these connections in engineering drawings can vary significantly, employing lines of different styles and thickness to denote various types of relationships.

For instance, solid lines might indicate primary connections or operational paths, while dashed or dotted lines could represent secondary or underlying connections that are not immediately visible.

The thickness of the lines might also vary to show the capacity or strength of the connection, such as a thicker line indicating a major power supply route versus a thinner line for a secondary circuit.

Solution: Detecting Connecting Lines With AI

Advanced computer vision algorithms are capable of detecting connecting lines in complex engineering drawings. Piping, electrical lines, walls, etc. can all be detected with over 98% accuracy:

Text Recognition

A critical yet challenging aspect of engineering drawing digitization involves the accurate interpretation and integration of textual content. Text in engineering drawings is not merely descriptive; it plays a pivotal role in differentiating between similar symbols, identifying connectors, and clarifying crucial information through annotations and codes.

Diversity of Textual Elements

Engineering diagrams often utilize a variety of fonts and styles to convey different types of information.

Codes are typically used to denote specific types of equipment or operational parameters, while annotations may provide critical insights into the design or operation that are not immediately apparent from the graphical elements alone.

The choice of font and style can vary widely, not only to indicate different information types but also to ensure that text is distinguishable in a complex visual context.

Challenges Posed by Text Overlaps

One of the most significant challenges in engineering drawing digitization is dealing with text overlaps.

In densely packed diagrams, text elements may overlap with symbols, connectors, or even other text, complicating the task of digitization.

These overlaps can obscure important details or lead to misinterpretation if not handled correctly during the digitization process.

The overlapping of text and graphical elements often necessitates advanced OCR (Optical Character Recognition) technologies that are capable of recognizing text even when it is partially obscured or merged with other drawing components.

Ensuring Clarity and Accuracy

Ensuring the clarity and accuracy of text in digitized engineering drawings is crucial for maintaining the functionality and integrity of the original documents.

This involves not only sophisticated recognition technology but also a deep understanding of how text interacts with graphical elements to convey complex information. Effective engineering drawing digitization must therefore include robust mechanisms for text recognition and error correction, enabling engineers and technicians to rely on digital drawings for accurate reproduction of technical details.

Looking for AI developers?

We create AI software — and we do it well. Talk to us to get your project started today

Trends In Engineering drawing digitization

As the field of engineering drawing digitization advances, Convolutional Neural Networks (CNNs) have emerged as a pivotal technology, driving significant improvements in the accuracy and efficiency of digitizing complex engineering drawings. CNNs, a class of deep neural networks, are particularly well-suited for image processing tasks due to their ability to detect patterns and features in images with high precision.

Enhanced Symbol and Shape Recognition

CNNs excel in recognizing and classifying various shapes and symbols in engineering drawings, even when these elements exhibit variations in size, orientation, or style. This capability is crucial for accurately converting detailed and intricate drawings into digital formats.

By training on extensive datasets of annotated engineering drawings, CNNs can learn to identify a wide range of symbols and shapes specific to different engineering fields, thereby increasing the reliability of digitized outputs.

Improved Text Recognition

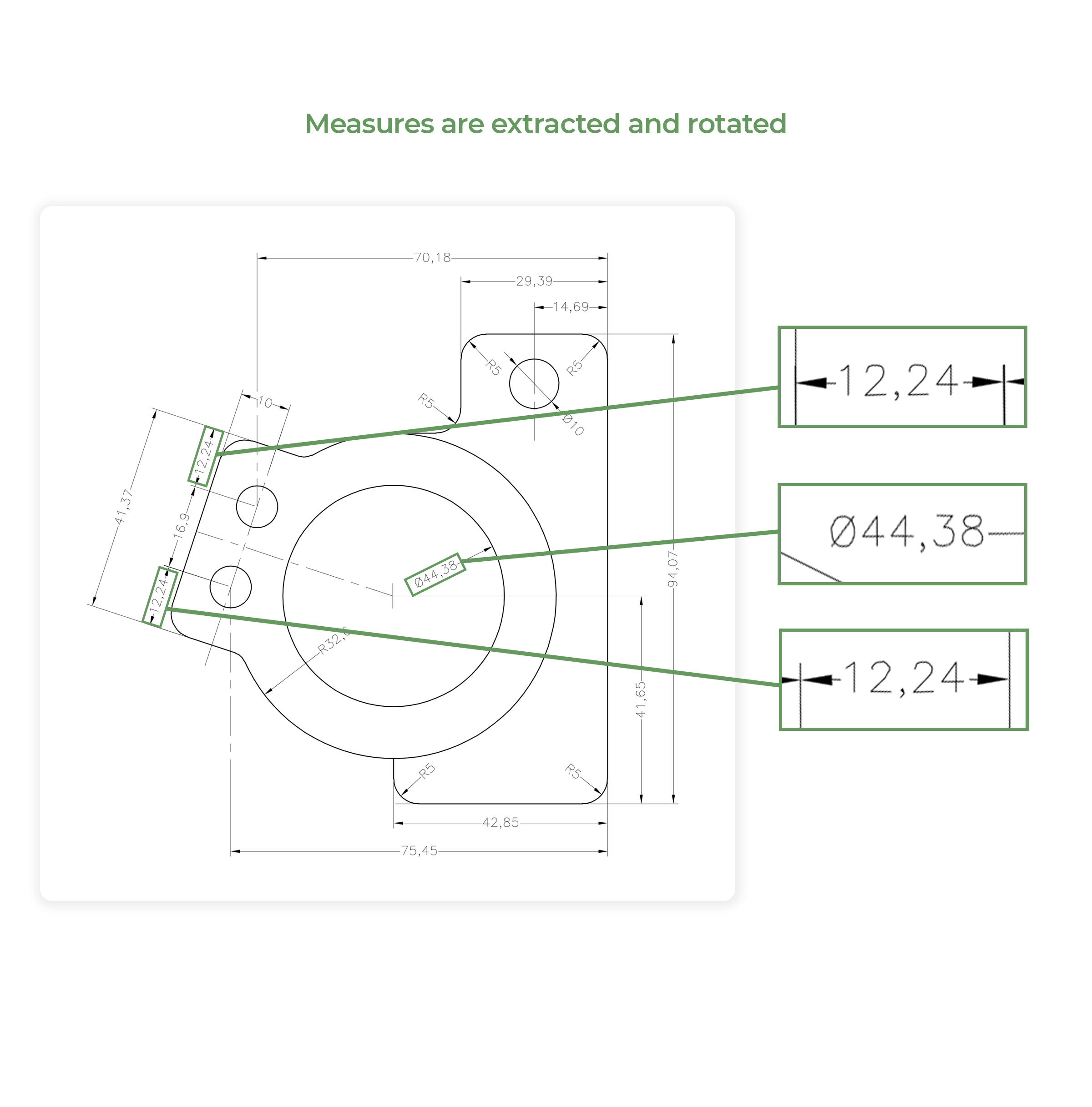

Text recognition within engineering drawings can be challenging due to overlapping elements, diverse fonts, and varying text orientations. CNNs are increasingly being utilized to enhance Optical Character Recognition (OCR) systems by providing more robust feature extraction capabilities.

This improvement allows for more accurate text detection and deciphering within crowded or complex diagrams, ensuring that annotations and codes are correctly captured during the digitization process.

Automation of Line Detection

CNNs are also instrumental in automating the detection of different line styles and thicknesses that represent various types of connections in engineering diagrams.

Through advanced pattern recognition, CNNs can distinguish between solid, dashed, and dotted lines, facilitating a deeper understanding of the physical and logical relationships depicted in the drawings.

This level of detail is essential for creating accurate digital replicas that retain all functional aspects of the original drawings.

Challenges and Future Directions

While CNNs offer substantial improvements in engineering drawing digitization, challenges remain in terms of training data requirements and computational resources.

Creating sufficiently large and well-annotated datasets for training these networks is time-consuming and costly. Moreover, the processing power needed to train and deploy CNNs for large-scale digitization projects can be substantial.

However, ongoing research and development are likely to continue enhancing the capabilities of CNNs in this field.

Future advancements may include more efficient network architectures that require less computational power and improved training techniques that can learn from smaller datasets or unsupervised data, further optimizing the digitization process.

Why choose Businessware Technologies as your software development company?

- Businessware Technologies is a reliable AI development vendor: it has been recognised as one of the top software development companies by Clutch and Manifest, it is a Top Rated Plus agency Upwork, and has received local awards for its excellent work,

- A team of over 70 highly skilled software engineers with extensive experience in developing complex software for both startups and Fortune 500 companies,

- Deep expertise in modern AI technologies and approaches to system development, like data science, machine learning, OpenCV, Python, Tesseract, and many more,

- Businessware Technologies is a Microsoft Gold Certified partner,

- Businessware Technologies is compliant with GDPR, ISO 9001, ISO 27001 standards,

- Businessware Technologies works with Fortune 500 companies and has had decades-long relationships with most of its clients,

- Businessware Technologies has proven to be a reliable AI outsourcing partner by having an excellent track record in AI and ML development backed by an extensive portfolio of successful projects.

If you have a computer vision project in mind and need help with implementation, contact our manager and they will be happy to help you.